Fuel gas treatment unit for gas engine generating plant

Currently, most of the oil and gas producing companies widely use gas engine power plant (GPP) for independent power supply of the main power units at oil and gas fields.

Contact us

Herewith, total installed capacities of GPP vary from one to dozens of MW. This allows you to engage associated petroleum gas (APG) in beneficial use in sufficiently large quantities to ensure the implementation of associated gas utilization program.

The first steps in this direction brought the oil, gas and mining companies to the adequate high quality preparation of fuel gas for gas engines of the generating units. The main problem, except for purifying of fuel gas from mechanical impurities and corrosive components (H2S, CO2), is reaching an acceptable methane number for the drive gas engine generating plant GPP.

In compliance with the attached diagram characterizing the relative dependence of GPP capacity changes on the methane number of the fuel gas mixture, we can assume that process modes of FGPU (fuel gas treatment unit) can increase the output capacity of the GPP up to 200% due to the increase of the methane number of the fuel gas, and decrease to minimum values the detonation load and overheating of the gas engine of the power generating plant.

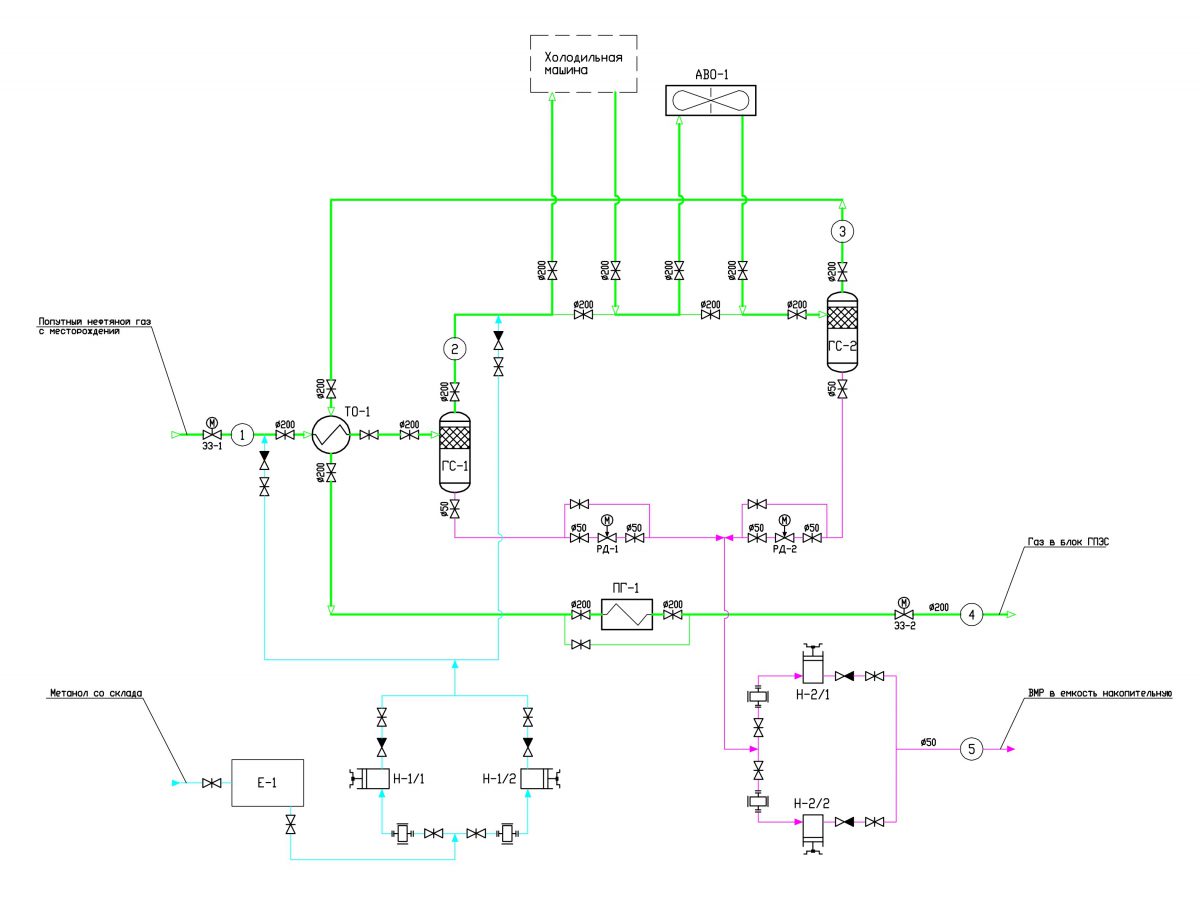

The pressurized petroleum gas enters an input of the recuperative heat exchanger ТО-1 and is pre-cooled by a flow of dry gas. Further, in the input gas separator the gas is mechanically purified from dropping liquid and mechanical impurities. The gas then passes cooling to minus 15 … 20°C in the evaporator of the refrigerating unit XM. During winter operation the gas can get the additional cooling in the air cooler due to low ambient temperature.

In the next gas separator GS-2 heavy hydrocarbon components are condensed in liquid form from the cooled gas stream, this increases the methane number of the petroleum gas to an estimated value of 75 … 80 units, and the purified gas stream via the recuperative heat exchanger is supplied into the GPP line; the gas can be heated if necessary in the flow heater ПГ-1 to a desired temperature. Technological part platform of FGTU can occupy an area of 30 meters x 40 meters. The equipment of the installation is located in block boxes with plant prefabricated bearing frame base, which are installed on the pile support. The input and output pipelines, power and control cable lines are also laid on the pile supports. Power consumption of power supply is up to 400 kVA, 380 V, 50 Hz.